Create articles from any YouTube video or use our API to get YouTube transcriptions

Start for freeThe Power of Production Process and Supply Chain Optimization

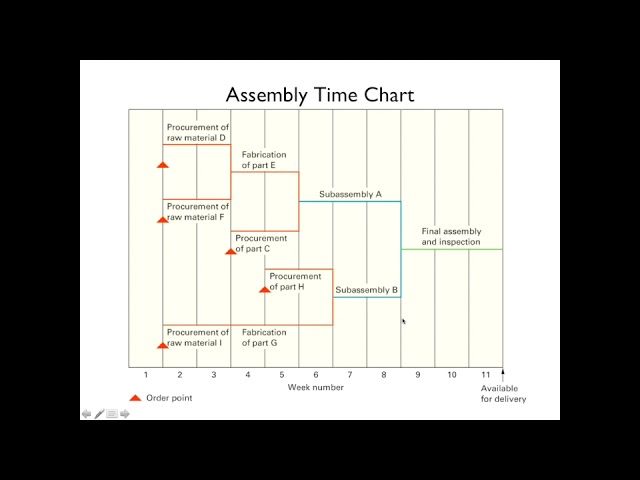

In the realm of manufacturing, entering the production process and supply chain optimization phase marks a pivotal moment. This stage, known as phase five, signifies that full production is underway, and it's time to fine-tune the process for maximum efficiency and effectiveness. The insights and adjustments made during this phase can substantially impact a product's quality, production speed, and overall costs, making it a critical step for manufacturers aiming to excel in the competitive market.

Learning from Production

As production progresses, the team accumulates valuable knowledge from the manufacturing experience. This learning curve is instrumental in identifying opportunities to enhance the production process. The team's ability to recommend how to manufacture the product in a more efficient or faster manner comes into play. For instance, finding ways to shorten programming and testing times can significantly boost capacity and throughput. This increase in efficiency not only speeds up production but also leads to cost reductions due to the streamlined process.

Enhancing Quality and Efficiency

The quest for quality and efficiency does not stop at speeding up the process. The production team also focuses on improving the product's quality by making adjustments to the assembly process or utilizing statistical data gathered during the initial production phases. These refinements could involve minor tweaks or more substantial changes, all aimed at elevating the product's quality.

Supply Chain Optimization

On the supply chain front, the shift to volume production presents an opportunity for further optimization. As production volumes increase, the supply chain team can leverage this scale to renegotiate costs with suppliers of materials and components. Achieving lower costs based on higher volumes is a strategic move that can significantly reduce the overall product cost.

The Goal: Optimizing Cost and Process

The overarching goal of this phase is to optimize every aspect of the production and supply chain process. By increasing efficiency, enhancing quality, and reducing costs, manufacturers can achieve a competitive edge. Both the production and supply chain teams work in tandem to identify and implement strategies that will lead to these outcomes. The focus on optimizing the entire process ensures that the product not only meets but exceeds market expectations.

In conclusion, the production process and supply chain optimization phase is crucial for any manufacturing project. It represents a period where the theoretical meets the practical, and the fine-tuning of the production line can lead to significant gains in efficiency, quality, and cost-effectiveness. Manufacturers that invest time and resources into this phase can expect to see a notable improvement in their product's market performance.

For more insights into how to navigate this critical phase in manufacturing, watch the full discussion here.