Create articles from any YouTube video or use our API to get YouTube transcriptions

Start for freeUnderstanding Supply Chain and Logistics

Supply chain management (SCM) involves a network of organizations, facilities, and activities focused on producing and delivering products or services. Logistics is a subset of SCM that deals with the forward and reverse flow of goods, services, cash, and information. A typical goods supply chain starts with multiple suppliers, moves through storage, manufacturing, more storage, distribution, retail, and ultimately to the customer. Service supply chains are usually simpler, with fewer suppliers and direct provision of services to customers.

The Flows of Supply Chain

In a supply chain, goods and services flow from suppliers to customers while cash flows in the opposite direction. Reverse logistics comes into play when customers return products, initiating a reverse flow of goods and cash.

Facilities in a Supply Chain

A variety of facilities are involved in the supply chain, including:

- Warehouses

- Factories

- Processing centers

- Distribution centers

- Retail outlets

- Offices for management and logistics

Functions and Activities Within Supply Chains

Key activities within a supply chain include:

- Forecasting

- Purchasing

- Inventory management

- Quality Assurance

- Scheduling production and delivery

- Customer service

What Is Supply Chain Management (SCM)?

SCM is the strategic coordination of various business functions within and across companies to integrate supply and demand management. Supply chain managers are responsible for managing supply and demand both within and across businesses, which includes planning, sourcing, transformation activities, and logistics.

Key Aspects of SCM

The goal of SCM is to match supply to demand as effectively and efficiently as possible. This involves managing outsourcing levels, procurement, supplier and customer relationships, and responding quickly to problems.

Trends in Supply Chain Management

Current trends in SCM include:

- Measuring SCM return on investment

- The greening of supply chains

- Reevaluating outsourcing decisions

- Integrating information technology

- Adopting lean principles

- Managing risks

Benefits and Risks of Outsourcing

Outsourcing can lead to lower labor costs, allowing companies to focus on core strengths, converting fixed costs into variable costs, freeing up capital, and shifting risks to suppliers. However, it also presents risks like inflexibility, increased transportation costs, language and cultural barriers, loss of jobs, loss of control, and potential for intellectual property theft.

Managing Supply Chain Risks

Risks in supply chains can include disruptions, supplier problems, and quality issues. Strategies for risk management involve risk avoidance, reduction, and sharing. Key elements of successful risk management include knowing suppliers, providing supply chain visibility, and developing event response capabilities.

Global Supply Chains

In global supply chains, product design and manufacturing may involve inputs from around the world. This adds complexities such as language and cultural differences, currency fluctuations, political instability, transportation costs, lead times, and the need for trust among supply chain partners.

Ethical Issues in Supply Chains

Ethical concerns in supply chains can range from bribery and exporting pollution to mislabeling country of origin and selling products abroad that are banned at home. Companies can address these issues by developing an ethical supply chain code of behavior, monitoring activities, choosing suppliers with a good ethical reputation, and incorporating labor standards into supplier contracts.

Small Business Concerns in SCM

Small businesses face unique challenges in SCM, including inventory management, the need for backup suppliers, and international trade complexities. They must also manage supplier relationships, ranging from short-term competitive bidding to long-term partnerships.

Procurement and Supplier Management

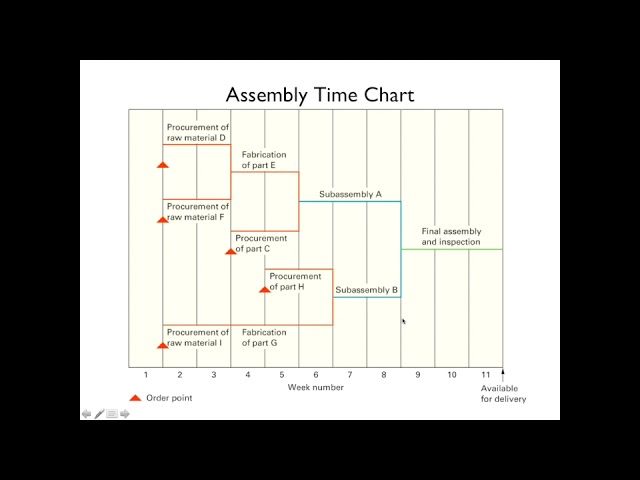

The procurement process aims to obtain materials, parts, and services required for production or service provision. It involves identifying sources of supply, negotiating contracts, and managing supplier relationships. This can also include strategic partnering, where businesses join for mutual benefits.

Logistics and Inventory Management

Logistics involves managing the movement of materials within a facility, as well as incoming and outgoing shipments. RFID technology has become a pivotal tool in improving supply chain visibility and inventory management. Third-party logistics (3PL) providers are also increasingly used for warehousing and distribution.

Creating an Effective Supply Chain

An effective supply chain requires strategic sourcing, trust, effective communication, quick information sharing (information velocity), supply chain visibility, event management capability, and performance metrics.

Conclusion

This comprehensive overview of supply chain management highlights the importance of understanding and optimizing the various components and flows within supply chains. As global economies evolve and consumer demands shift, effective SCM becomes increasingly vital for businesses to maintain competitiveness and achieve success.

For more detailed insights into supply chain management, watch the full lecture on YouTube.