Create articles from any YouTube video or use our API to get YouTube transcriptions

Start for freeIntroduction to Bioreactors

Bioreactors are fundamental tools in the field of biotechnology, playing a crucial role in various industrial and research applications. These sophisticated devices provide controlled environments for biological processes, enabling the production of valuable compounds and the study of complex biological systems.

What is a Bioreactor?

A bioreactor is a closed container designed to facilitate biological processes under carefully controlled conditions. It serves as a fermentation vessel used in the synthesis of numerous chemicals and biological products. The primary function of a bioreactor is to create an optimal environment for cultivating microorganisms and removing waste biomass along with their products.

Key features of a bioreactor include:

- Regulation of parameters such as temperature, pH, pressure, and nutrient levels

- Agitation systems for mixing cells and medium

- Aeration systems for oxygen supply in aerobic processes

- Mechanisms for withdrawing cells and medium

- Sterilization capabilities and maintenance of sterility

Bioreactors are instrumental in producing a wide range of products, including biomass, metabolites, and antibiotics.

Design Principles of Bioreactors

The design and operation of a bioreactor are tailored to meet specific requirements based on several factors:

- The type of organism being cultivated

- Optimal conditions needed for product formation

- The value of the intended product

- Scale of production

A well-designed bioreactor aims to increase productivity while reducing costs and improving product quality. To achieve these goals, bioreactors incorporate various systems and features:

- Agitation system

- Oxygen delivery system

- Foam control system

- Sampling ports

- Cleaning and sterilization systems

- Charging and emptying lines

- Temperature and pH control systems

Material Considerations

The materials used in constructing bioreactors must meet several critical criteria:

- Non-corrosive properties

- Free from toxic compounds that could contaminate the fermentation medium

- Ability to withstand steam sterilization procedures

- Capacity to endure high pressure and pH variations

Scale and Applications

Bioreactors come in various sizes, ranging from small laboratory-scale devices to large industrial units. The scale of a bioreactor depends on its intended use:

- Microbial cell culture

- Shake flasks for small-scale experiments

- Laboratory-size fermentors

- Pilot-level plants

- Large-scale industrial applications

Principles of Bioreactor Operation

The fundamental principle behind bioreactor operation is to provide an optimal environment for microorganisms to grow and produce desired metabolites. Bioreactors facilitate:

- Optimal growth conditions for microorganisms

- Production of metabolites

- Biotransformation of substrates

- Bioconversion of materials into valuable products

The design of a bioreactor is tailored to the specific needs of the organisms being cultivated and the desired products. These versatile devices can be used for various purposes, including:

- Enzyme production

- Biocatalysis processes

- Conversion of biological materials into usable goods

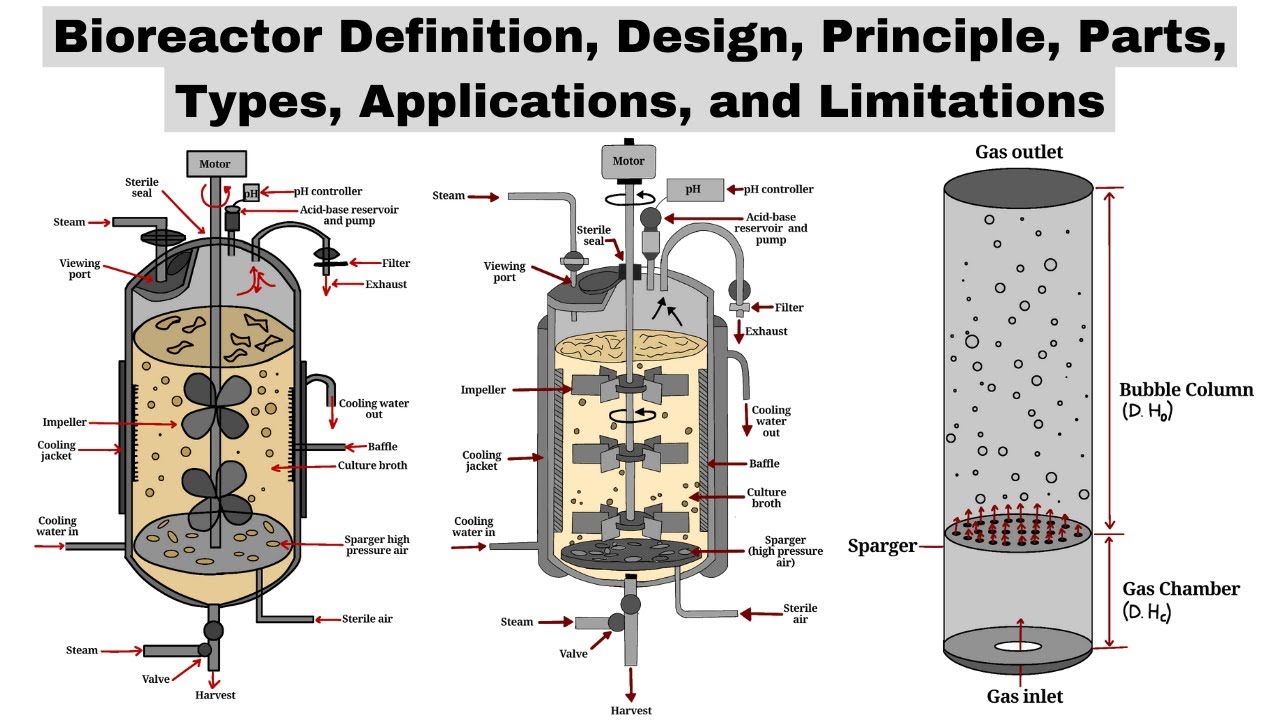

Components of a Bioreactor and Their Functions

A typical bioreactor consists of several key components, each serving a specific function in maintaining optimal conditions for biological processes.

1. Fermentor Vessel

The fermentor vessel is the main body of the bioreactor. It is typically a large cylinder with closed top and bottom, connected to various pipelines and valves. Two common types of fermentor vessels are:

- Glass vessels: Used in small-scale operations, non-toxic, and corrosion-resistant

- Stainless steel vessels: Employed in large-scale industries, capable of withstanding corrosion and pressure

2. Heating and Cooling Apparatus

Temperature control is crucial in bioreactor operations. The heating and cooling system typically includes:

- A cooling jacket surrounding the fermentor vessel

- Thermostatically controlled baths or internal coils for heating

- Silicon jackets for heat dissipation

These components work together to maintain the optimal temperature for the biological process and assist in sterilizing the nutrient medium.

3. Aeration System

The aeration system is vital for maintaining optimal oxygen levels in aerobic processes. It consists of two main components:

- Sparger: Distributes air or oxygen throughout the culture medium

- Impeller: Assists in mixing gas bubbles and microbial cells throughout the medium

4. Sealing Assembly

The sealing assembly ensures proper agitation by sealing the stirrer shaft in the fermentor. Three types of sealing assemblies are commonly used:

- Stuffing box

- Mechanical seal

- Magnetic drives

5. Baffles

Baffles are metal strips attached to the wall of the fermentor. They serve to:

- Reduce vortices

- Increase aeration efficiency

6. Impellers

Impellers are crucial for maintaining a uniform suspension of microbial cells in the nutrient medium. They consist of motorized blades mounted on the lid. Common types of impellers include:

- Disc turbines

- Open turbines

- Variable pitch turbines

7. Sparger

The sparger is responsible for providing sterile air to the fermentation tank. It typically consists of spiral pipes with small holes (5-10 mm) through which pressurized air is discharged. Types of spargers include:

- Porous spargers

- Sparger nozzles

- Combined agitator and sparger systems

8. Feed Ports

Feed ports, often made of silicon tubes, are used to replenish the fermentor with nutrients, acids, or alkalis. They allow for the sterile addition or removal of products.

9. Foam Control

Foam control is essential to prevent contamination and maintain optimal conditions. It typically consists of:

- Foam sensor

- Control unit

10. Valves

Valves regulate the flow of liquids in the fermentor. Common types include:

- Globe valves

- Butterfly valves

- Ball valves

- Diaphragm valves

Safety valves are also incorporated into the air and pipe layout to manage pressure.

11. Environmental Control Devices

Various devices are used to monitor and control environmental factors such as:

- Temperature

- Oxygen concentration

- pH

- Cell mass

- Nutrient levels

- Product concentration

12. Computer Integration

Modern fermentors are often integrated with computers and databases for:

- Effective process monitoring

- Data collection

- Automated or semi-automated control

Types of Bioreactors

Bioreactors come in various designs, each suited for specific applications and processes. Here are some of the most commonly used types in industries:

1. Continuous Stirred Tank Fermentor

This is the most widely used type of industrial bioreactor. Key features include:

- Cylindrical vessel with one or more agitators on a central shaft

- Motor-powered impeller agitators

- Sparger for improved gas distribution

- Simple temperature control

- Inexpensive construction

- Easy operation and cleaning

2. Airlift Fermentor

Also known as a tower reactor, the airlift fermentor is designed for efficient gas-liquid or gas-liquid-solid contact. Characteristics include:

- Divided fluid volume (riser and downcomer zones)

- Gas sparging in only one zone

- No moving parts or agitators

- Easy sterilization

- Low energy requirements

- Cost-effective

3. Bubble Column Fermentor

This type of bioreactor consists of a cylindrical vessel with a gas sparger at the base. Features include:

- Use of perforated pipes, plates, or metal microporous spargers

- Internal devices like horizontal perforated plates or vertical baffles

- Low operating costs

- Simple design

- Minimal maintenance requirements

4. Fluidized Bed Fermentor

Fluidized bed bioreactors use smaller particles in beds to overcome issues associated with packed bed reactors. Characteristics include:

- Improved mass transfer, oxygen transfer, and nutrient delivery

- Uniform temperature maintenance

- Easy catalyst replacement and regeneration

- Shorter gas-solid contact times

5. Packed Bed Fermentor

Also known as fixed bed reactors, packed bed fermentors contain a solid particle matrix. Features include:

- Operation in submerged mode (with or without aeration) or trickle flow mode

- High catalyst conversion rate

- Simple operation

- Low construction and operating costs

- Increased reactant and catalyst contact

6. Photobioreactor

Photobioreactors are specially designed for organisms that require light for growth. Characteristics include:

- Use of natural sunlight or artificial light

- Construction from glass or transparent plastic

- Various designs: helical wound tubular loop, flat panel, continuous run tube loop, multiple parallel tube

- Temperature range of 25-40°C

7. Membrane Bioreactor

Membrane bioreactors combine conventional treatment with membrane filtration. Features include:

- Removal of organic and suspended particles

- High nutrient level reduction

- Membrane pore sizes ranging from 0.035 to 0.4 microns

- Compact design

- Efficient control of microorganisms

Applications of Bioreactors

Bioreactors find applications in various industries and research fields. Here are some key applications for different types of bioreactors:

Stirred Tank Fermentors

- Antibiotic production

- Citric acid production

- Exopolysaccharide synthesis

- Cellulose production

- Enzyme production (e.g., keratinolytic enzymes, lactase, cellulase)

- Tissue mass culture

- Lipase production

- Polygalacturonase production

- Succinic acid production

Bubble Column Fermentors

- Algal culture

- Keratinolytic enzyme production

Airlift Fermentors

- Antibiotic production

- Keratinolytic enzyme production

- Exopolysaccharide synthesis

- Acrylic acid production

- Lactic acid production

- Tissue mass culture

Fluidized Bed Fermentors

- Lactase production

Packed Bed Fermentors

- Lactase production

- Hydrogen production

- Organic acid synthesis

- Mammalian cell culture

Photobioreactors

- Microalgae and cyanobacteria cultivation

- Production of compounds like astaxanthin and beta-carotene

Membrane Bioreactors

- Wastewater treatment

- Water quality management

- Remediation of contaminated soil

- Alginate production

- Antibiotic production

- Cellulose hydrolysis

- Hydrogen production

- Volatile organic compound treatment

Limitations of Bioreactors

While bioreactors offer numerous advantages, they also have certain limitations that vary depending on the type of bioreactor:

Stirred Tank Fermentors

- High shear stress

- High power consumption

- Presence of moving internal parts

Bubble Column Bioreactors

- Slow photosynthetic efficiency

Airlift Fermentors

- Non-uniform nutrient supply

- Insufficient mixing

- High viscosity can limit bulk circulation

Fluidized Bed Fermentors

- Common particle breakup

- Increased reactor vessel size

- Difficulty in predicting bubbling beds of fine particles

- Erosion of pipe and vessel walls due to particle abrasion

Packed Bed Fermentors

- Undesired heat gradients

- Poor temperature control

- Difficulty in replacing catalysts

Photobioreactors

- Reliability issues

- Temperature maintenance challenges

- Lack of effective cooling

- Need for periodic cleaning due to light exposure

- Requirement for maximum light exposure

Membrane Bioreactors

- Biofilm overgrowth leading to periodic cleaning

- Potential membrane rupture at high flow rates

Conclusion

Bioreactors are indispensable tools in modern biotechnology, offering controlled environments for a wide range of biological processes. From small-scale laboratory experiments to large industrial applications, these versatile devices play a crucial role in the production of valuable compounds and the advancement of scientific research.

Understanding the design principles, components, and various types of bioreactors is essential for researchers and industry professionals working in biotechnology, pharmaceuticals, and related fields. By carefully selecting and optimizing bioreactor systems, it's possible to enhance productivity, reduce costs, and improve the quality of biologically derived products.

As technology continues to advance, we can expect further innovations in bioreactor design and operation, leading to even more efficient and sustainable bioprocesses. The ongoing development of bioreactor technology will undoubtedly contribute to solving global challenges in areas such as healthcare, environmental remediation, and sustainable production of chemicals and materials.

Article created from: https://www.youtube.com/watch?v=azdVSr7DBlg